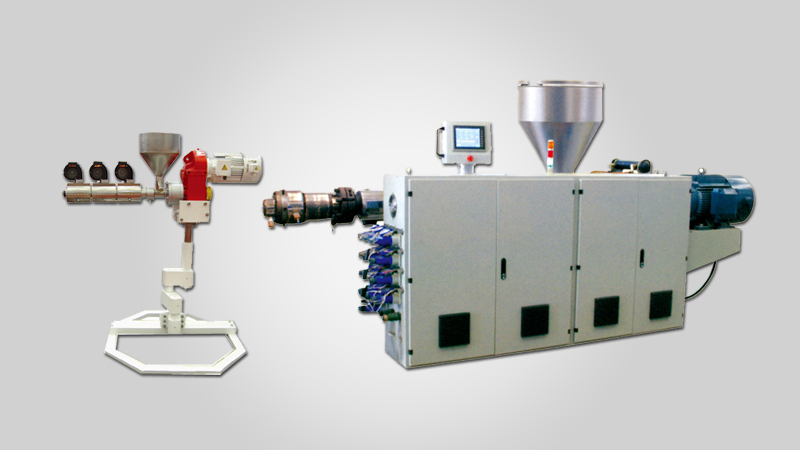

SJ Series Ib Ntsia Hlau Extruder

Tswv yim tsim

1.High ceev extruding raws li zoo

2.Medium & tsis tshua muaj kub plasticity tswvyim guarantees qhov zoo ntawm cov khoom extruding.

3.High hardness thiab degree ntawm tiav, tsis tshua muaj suab nrov.

4.PLC ntse tswj, yooj yim txuas nrog lub tshuab pab.

5.Strict kub tswj system ua ke cua thiab dej txias ua ke.

6.Comprehensive mixing tsim guarantees cov nyhuv mixing.

7.Supper thawb quab yuam bearing muab lub siab toque tso zis.

Tus qauv tsim

Ib leeg ntsia hlau extuder yog tsim los ntawm nias kaw lus, kis tau tus mob thiab cua sov system.

Khoom nta

1. Lub ntsej muag tawv lub thawv;DC los yog AC CVT ceev kho.

2.Tshiab hom ntsia hlau qauv ua rau yaj thiab sib tov txawm thiab lav lub peev xwm ntau lawm nrog tsawg melting kub.

3.Cast tooj liab los yog aluminium rhaub;cua los yog dej txias raws li qhov xav tau sib txawv.

4.Barrel yog ua los ntawm cov khoom tshwj xeeb thiab tuaj yeem kho nitriding.

5.Advanced hluav taws xob tswj qhov system.

Qhov Zoo Thiab Qhov Tsis Zoo

Qhov zoo:Tus nqi qis nrog kev tsim qauv yooj yim, daim ntawv thov dav

Qhov tsis zoo:

1.Cov ntaub ntawv kis tau tus mob ntawm ib leeg ntsia hlau extruder cia siab rau kev puas tsuaj thiab qhov no txwv tsis pub cov khoom noj, hmoov, cov khoom tsis zoo, cov iav fiber ntau thiab cov khoom siv tsis zoo yog qhov nyuaj rau pub.

2.Thaum lub taub hau tuag siab tau txais qhov siab ntawm contra-flow tshwm sim ua kom ua tau zoo.

3.Cov roj ntws tawm ntawm ib qho ntsia hlau extruder tsis zoo.

4.Single ntsia hlau extruder tsis muaj feem xyuam rau qee cov txheej txheem tsim khoom piv txwv li cov khoom siv thermal ua.

Main Technical Parameters

| Qauv | (L/D) | Cov zis (kg / h) | Ceev (r/min) | Lub zog tsav (kw) | Center Qhov siab (mm) |

| SJ-25 | 25/1 | 5 | 20-120 Nws | 2.2 | 1000 |

| SJ-30 | 25/1 | 10 | 20-180 Nws | 5.5 | 1000 |

| SJ-45 | 25-33/1 ib | 50-150 | 20-150 | 7.5-22.0 Nws | 1000 |

| SJ-65 | 25-33/1 ib | 60-250 | 20-150 | 15-90 : kuv | 1000 |

| SJ-75 | 25-33/1 ib | 100-350 | 20-150 | 22-110 : kuv | 1100 |

| SJ-90 | 25-33/1 ib | 180-550 : kuv | 20-110 : kuv | 30-185 : kuv | 1000-1100 Nws |

| SJ-120 | 25-33/1 ib | 320-800 Nws | 20-90 Nws | 55-280 : kuv | 1000-1250 |

| SJ-150 | 25-33/1 ib | 400-1200 Nws | 20-75 : kuv | 90-355 : kuv | 1000-1300 Nws |